The construction industry faces several challenges, including:

-

Lack of Collaboration

-

Late Supply Chain Engagement (MEP engineers)

-

Poor Design Coordination

-

Clients’ Late Changes

-

Labour Shortage and Labour Inflation

-

Weak Labour Productivity

-

Technology Challenges.

We want to:

-

Introduce an efficient procurement framework such as Integrated Project Delivery.

-

Develop new processes, including DFMA, Offsite construction/MMC, and Digital data strategy.

-

Test and develop new technology such as Generative Design AI.

GLIGE stands for Generative Design (AI), Lean and Integrated processes, Group for teamwork and Efficiency.

This website is a Proof of Concept during GLIGE's early development. Please leave feedback at the bottom of this page to help us assess whether we're on the right track to resolve your construction challenges.

Construction Challenges

Traditional Procurement and Poor Design Coordination

-

72% of respondents to our survey encounter late design changes very frequently due to poor coordination with Mechanical and Electrical engineers. Only 1% said it is straightforward to deal with.

-

In the Traditional Procurement (D&B), Mechanical and Electrical subcontractors are coordinated late in the project, leading to late design changes with knock-on effects across the design of the whole building.

-

Traditional Procurement does not support strong collaboration among project members.

Labour

-

Gleeds’ UK Construction Market Report Q3 2025 highlights that 75% of contractors noticed increases in labour rates.

-

54% of contractor respondents reported labour availability issues.

-

Construction Output per worker stands below the UK economy average (source: ONS).

Client

-

56% of respondents to our survey found that the client’s late changes are very frequent, and only 3% said it is straightforward to deal with them.

Technology

-

Only 3% of the interviewees mentioned that it is straightforward to work with different 2D/3D design models and to maximise digital data quality and accuracy.

-

All interviewees agreed that the main problems in information management are the use of multiple, unconnected information sources and challenges with software interoperability.

Technical Design Development

-

Only 3% of the interviewees said that technical design development at RIBA stages 4-5 is straightforward

SOLUTIONS

No single process, software, or AI tool will fix all the pain points we identified in interviews and surveys with construction players.

Only a combination of efficient procurement, new processes and new technology can help the construction industry.

We propose:

-

A new Procurement under the Integrated Project Delivery framework.

-

Early Contractor, Subcontractors and Supply Chain Involvement.

-

Early Design Freeze.

-

Offsite and Modern Method of Construction (MMC).

-

Design for Manufacture and Assembly, BIM library and Generative Design (AI).

-

Data Strategy at the Outset.

INTEGRATED PROJECT DELIVERY

Integrated project delivery (IPD) will improve collaboration among construction project members, who are typically characterised by adversarial and fragmented relationships.

IPD will support early contractor and supply chain engagement and help address issues with weak tender documents.

Integrated Project Delivery (IPD)

The American Institute of Architects (AIA, 2007) defines Integrated Project Delivery (IPD) as a project delivery approach that integrates people, systems, business structures and practices into a process that collaboratively harnesses the talents and insights of all participant to optimise project results, increase value for the owner, reduce waste, and maximize efficiency through all phases of design, fabrication and construction.

The 9 principles of the IPD

-

Multi-party agreement

-

Mutual respect and trust

-

Mutual benefits and rewards

-

Collaborative innovation and decision making

-

Early involvement of key participants

-

Early goal definition

-

Intensified planning

-

Open communication

-

Organisation and leadership

The first benefit of the Integrated Project Delivery (IPD)

The most striking difference between IPD and the more traditional delivery methods (e.g., Lump Sum, etc.) is the use of a single multi-party agreement, in which all major parties to the project execute the same agreement and share the risks and potential rewards (Lancaster and Tobin, 2010).

The second benefit of the Integrated Project Delivery (IPD)

IPD leverages early engagement and early contributions from team members' expertise. At the core of an integrated project are collaborative, integrated and productive teams composed of key project participants.

EARLY SUPPLY CHAIN INVOLVEMENT

-

Evidence from 20,000 projects in the database of ‘Independent Project Analysis’ revealed that projects with the best early-stage planning and front-end loading have shown to improve cost and schedule performance by 10%.

-

M&E Contractors expressed a preference for schemes where they can engage early and have a design at a stage that allows for early procurement rather than inheriting a poor design (at RIBA 3) and having to go back to first principles (source: M&E contractor survey June 2024).

-

The table below shows the profitability of construction projects based on the contractual types. The margin for projects ranges from -1.41% to 43.67%. Early contract involvement shows strong average gross profit margin at 21.32% (source: Muhammad Bilal, Journal of Building Engineering, 2019).

EARLY DESIGN FREEZE AND

EARLY DEVELOPMENT

Early Design Development and Early Design Freeze

-

Integrated Project Delivery (IPD) requires moving the design decisions early and upstream as far as possible to where they are more effective and less costly (see cost of design changes in the chart above).

-

IPD integrates early input from constructors, subcontractors and suppliers as well as from designers, and it uses BIM tools to model and simulate the project accurately.

-

The result of the Integrated Project delivery is that the project is defined and coordinated to a much higher level before the tendering of the contractor and before the construction start, enabling a more efficient Construction phase, fewer Costly Late Changes and stronger tender documents

-

Early Design Freeze will help to reduce the Client’s Late Changes.

Offsite Construction

-

Early design development and Early design freeze are prerequisites to implement Off-site construction and MMC.

-

According to McKinsey, Modular projects currently tend to take longer to design than traditional projects, as designers learn to align with the manufacturing process. Design decisions need to be made up front, and changes later in the process are both more costly and more difficult.

OFFSITE AND MODERN METHOD OF CONSTRUCTION (MMC)

-

McKinsey noted that MMC and modular construction are faster than traditional construction delivery methods and can cut construction schedules by -20% to -50%.

-

Offsite/MMC improves the quality of the building and is more sustainable, thanks to lower construction waste and lower full-life costs. Off-site and MMC are safer with fewer accidents on the construction site.

-

Most of the benefits associated with Off-site stem from the lean manufacturing process, where most construction activities are carried out in a controlled factory environment, enabling coordinated, repeatable tasks and greater automation.

-

Offsite manufacturing can take place in parallel with foundation work, unlike a traditional project.

Offsite Construction benefits, according to scientific research:

Costs in Offsite and MMC

According to McKinsey, there is an opportunity in Offsite/MMC construction for -20% cost saving but at a risk of up to +10% cost increases if labour savings are outweighed by logistics or materials costs:

-

McKinsey expects that offsite/MMC can reduce the labour costs on a project by up to -25%. Some of the most skill-intensive and expensive work (mechanical, electrical, and plumbing) can be handled by lower-cost manufacturing workers, reducing the wage bill.

-

Automation will aim to offer an exponential boost to productivity on Off-site/Modular construction compared to traditional methods today.

-

Modular projects tend to have higher upfront design costs, but lower costs for rework and redesign.

-

Modular construction already has a proven track record of reducing project schedules, which in turn holds down the cost of site overheads.

-

Overall Material Costs reduction in the order of -5 to -10 percent may be achievable:

-

Material cost increases are mainly because automated facilities require more precise material tolerances, raising material quality standards and costs.

-

Second, some duplication of materials is required to produce a transportable product.

-

Offsetting this is that builders can save on the cost of materials by centralising procurement for a factory, rather than making multiple smaller purchases for individual projects.

Offsite and MMC challenges

-

According to a contractor's survey, interviewees mentioned the lack of design flexibility, as the offsite-manufactured framing system required a 2-ft grid, making it impossible to design a circular or oval building.

-

Interviewees encountered challenges related to the system standards when trying to connect the Off-site manufactured system to the concrete podium because the manufactured framing system's tolerances were much stricter than what the construction industry allows, given that the off-site framing manufacturer has low tolerances on the variation in the surface of the concrete slab. (Source: John Killingsworth, Mohammed Hashem Mehany and Hana Ladhari.)

Offsite and MMC implementation

Key solutions to several construction challenges highlighted earlier on this website will also serve as crucial enablers for the implementation of Offsite and MMC.

Design for Manufacture and Assembly (DfMA)

Design for Manufacture and Assembly (DfMA) can improve the standardisation of building components to facilitate easy specification and replication.

DfMA will help Offsite and MMC manufacturers to improve design flexibility, expand demand pipelines, and gain economies of scale.

Ashley cited a survey of DfMA users conducted by Boothroyd Dewhurst Inc. found the typical results include (Shang Gao, Ruoyu Jin & Weisheng Lu, 2019):

-

51% reduction in parts count

-

37% decrease in parts cost

-

50% faster time-to-market

-

68% improvement in quality and reliability

-

62% drop in assembly time

-

57% reduction in manufacturing cycle time

According to Boothroyd (2005), DfMA provides a methodology for evaluating and improving product design by considering downstream manufacturing and assembly processes. It thereby signifies a shift from traditional, sequential design thinking to non-linear methods.

DFMA GUIDELINES: a) Design for ease of fabrication to reduce time and cost by eliminating complex fixtures and tooling; b) Design for simple part orientation and handling; c) Design with predetermined assembly technique in mind; d) Consider modular design due to simplified design and assembly; e) Consider design for mechanised or automated assembly, f) Use standard and off the shelf component to reduce purchasing lead time and costs; g) Use as similar material as possible; h) Minimise precast component types to simplify design, manufacture and assembly; i) Minimise connector type and quantity; l) Minimise the use of fragile parts; m) Do not over-specify tolerances or surface finish to reduce costs with easier manufacture.

DFMA-oriented Parametric Design

BIM Parametric Feature

BIM is the supporting technology for implementing DFMA, as it reduces design coordination errors and costly late rework.

The most striking feature of BIM is its parametric design, in which all building entities are represented as components (e.g., a BIM library of building components).

An existing BIM library of building elements will help designers and engineers during the Technical Design phase by reducing time and errors.

We will develop libraries of building modules for the manufacturing process, accelerated and simplified through automated design (Generative Design), thereby shortening the design period.

DFMA-oriented Parametric Design

DFMA-oriented parametric design, a new design philosophy, is the organic combination of DFMA and BIM parametric design.

It means that designers not only consider the requirements of the design stage but also those of the manufacturing and assembly stages when using BIM technology to design an Offsite/MMC building.

What is it about?

Compared with the traditional design process, the DFMA-oriented parametric design process adds:

-

Split design analysis and DFMA analysis to determine which components of a building should be manufactured Off-site.

-

Considers the requirements of the manufacturing and assembly stages.

-

Establishes a standard parametric precast component library via the redevelopment and family templates of BIM, and expands BIM functions needed for precast component assembly.

The output of DFMA-oriented parametric design is an Offsite/MMC building construction information model and precast components production information models, rather than numerous static 2D drawings.

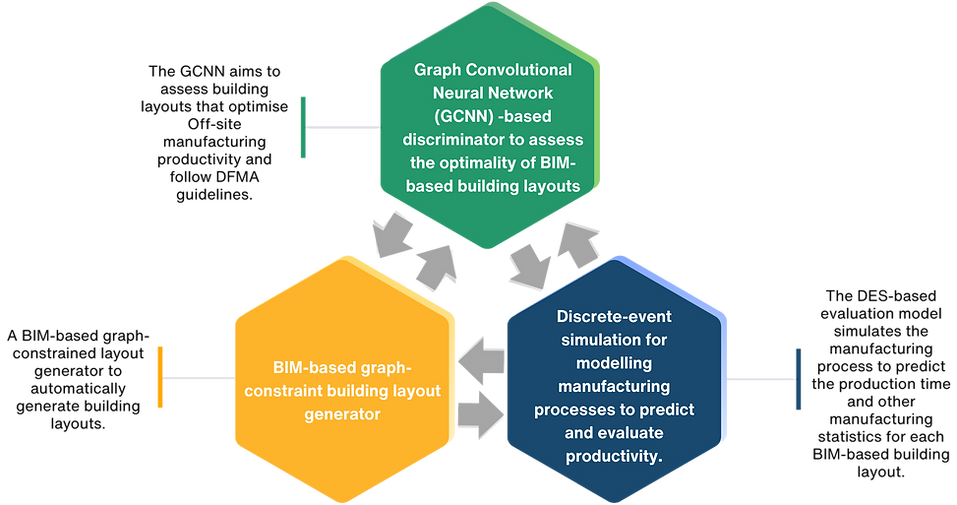

Generative Design (AI)

The video below illustrates the proposed Generative AI framework designed to optimise productivity in Off-site manufacturing. We will further develop the Generative AI framework to optimise DFMA.

Generative AI will help optimise DfMA guidelines and overcome design and economy-of-scale constraints in Offsite and MMC.

-

Generative design (AI) refers to employing algorithms and computational geometry to systematically explore an extensive design space, iteratively refining options based on defined parameters and objectives. Because the possible design permutations are vast, generative design approaches offer a comprehensive, automated exploration that is often not feasible for human designers.

-

Generative Design (AI) holds promise during the (early) design phase, where it involves considerations spanning structural integrity, efficiency, construction process, cost effectiveness, and the optimisation of DFMA guidelines.

-

Generative Design will become a valuable tool in predicting various performance aspects in building design, capable of providing detailed and simplified simulations for parameterised components during the design phase.

Digital Data strategy

A robust Digital Data Strategy is paramount for resolving technological challenges such as 3D/2D design Coordination, Software Interoperability, and Digital Data quality.

Digital Data Strategy at the outset

Establish clear information requirements at the start of a construction project. Define specific functionalities, formats, and file types for compliance. Use open standards like IFC for interoperability. Mandate 3D models for architects, engineers, and subcontractors.

Assign clear responsibilities to all contributors involved in providing these information requirements. Appoint a dedicated coordinator.

Implement data quality standards at the start of the project, focusing on accuracy, relevance, consistency, transparency, and timeliness. Set up data quality checks at the point of data entry to address errors early.

Conduct regular data reviews and audits. utilise techniques such as spot checks, data profiling, sampling, and quality scorecards.

Digital readiness in the value chain

Collaborate with players that have solid digital capabilities from architects to M&E subcontractors and suppliers.

Support the use of a common vendor digital platform and software, such as Autodesk software suites (Revit and Navisworks files are well supported in the standard vendor system), to make interoperability and digital coordination in the construction value chain easier.

We will search the market for tools that facilitate the exchange of open data among different design software, the CDE, and the CFAM platform. If not available, we will develop API software and a customer export template to improve interoperability and digital coordination.

Establish data stewardship

Comprehensive training on data quality standards and best practices is needed. They will have the authority to enforce data quality rules and make any necessary corrections.